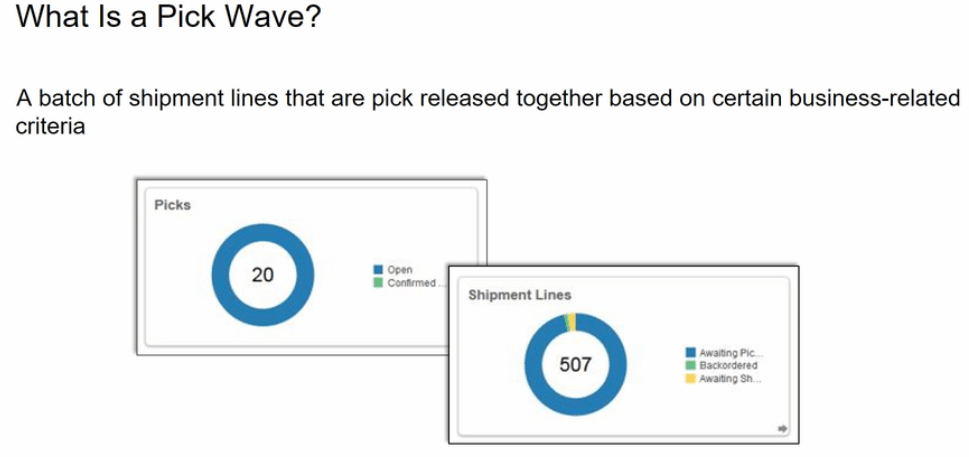

When is Pick Wave used

It is used most Often for

- Fulfilling a particular customer demand

- Optimizing transportation

- Fulfilling backorders to reduce delay in shipment

Steps of Pick Wave

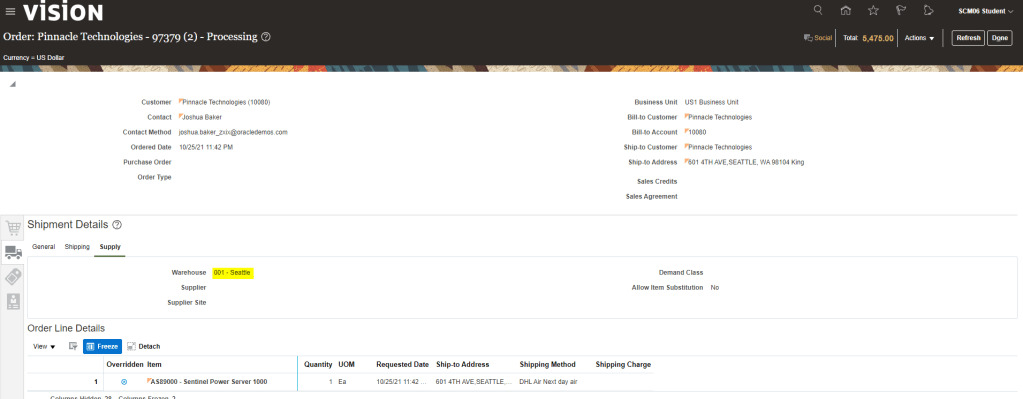

Step1: Create Order

- Create Order with Supply Warehouse as Seattle. Ensure Line status of this Order is “Awaiting Shipping”.

Step 2: Ensure Inventory Organization has Pick Confirmation Required as Unchecked

- Inventory Organization should have Pick Confirmation Required Unchecked else even if we try for Auto Pick Confirm, it will not proceed further.

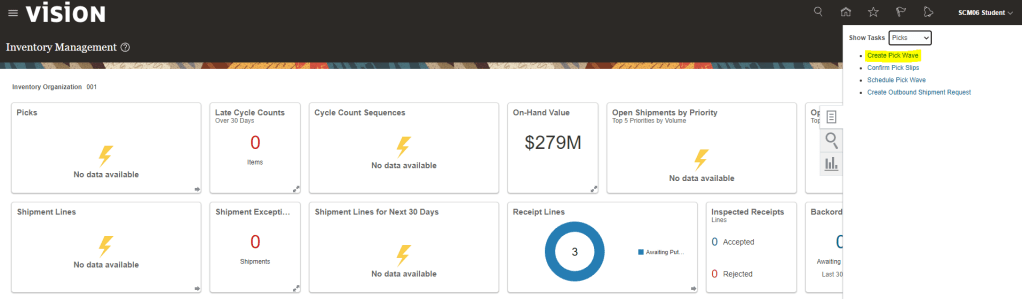

Step 3: Create Pick Wave

- Navigation: Go to Supply chain Execution -> Inventory Management -> Go to Task Panel tab -> Select Picks -> Choose Option “Create Pick Waves”

- Enter Following Details

- Inventory Organization at Top Right Corner should be “001”.

- Release Rule : 001-Auto Pick Conf. This rule is a task which can be viewed at “Manage Pick Wave Release Rule“.

- Order Type : Sales Order

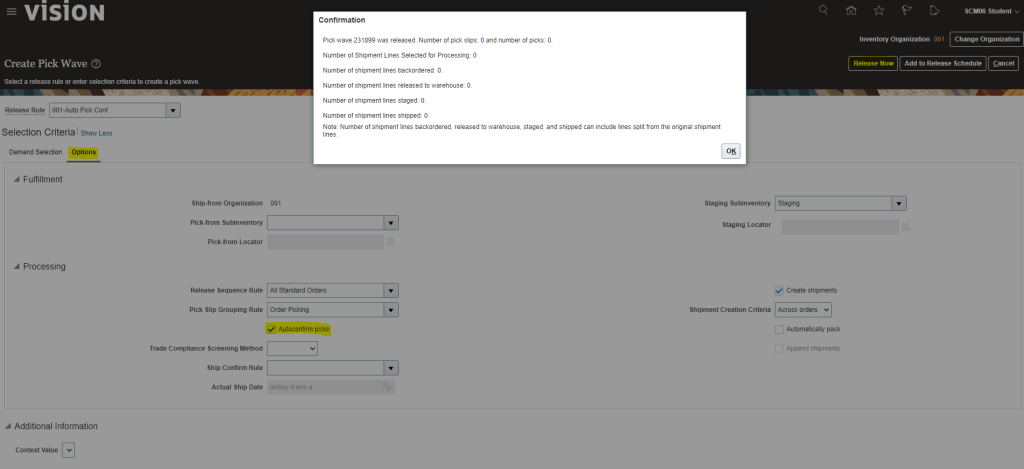

- After entering Above Details, Click on “Show More“. Click on Options Tab

- Ensure AutoConfirm Picks is Checked.

- Click on Release Now.

- On clicking Release Now, Pick Wave Number will be generated along with Number of Pick Slips as “1” and Number of Picks as “1”.

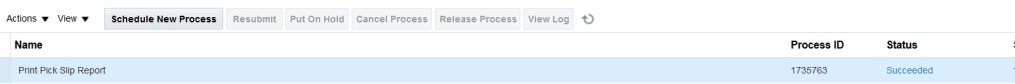

- A Job “Print Pick Slip Report” gets scheduled, which can be viewed by going to Tools-> Scheduled Job.

Once Job completes, see attachment to view the Pick Slip Report.

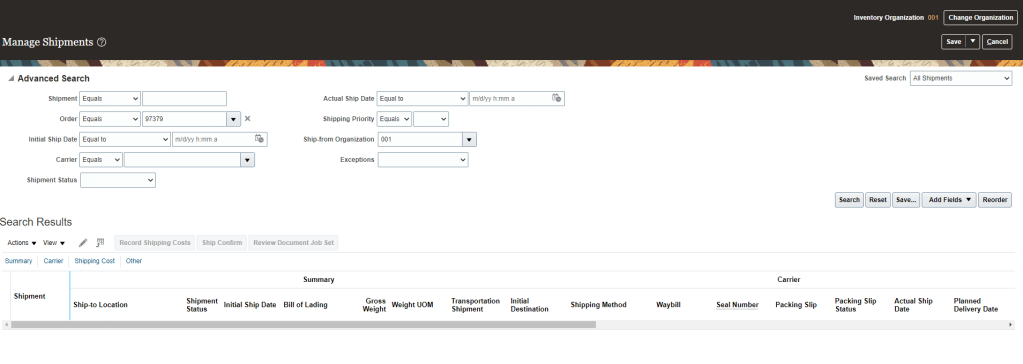

Step 4: View Shipment

- Navigation: Go to Supply chain Execution -> Inventory Management -> Go to Task Panel tab -> Select Shipments -> Choose Option “Manage Shipments”.

- Enter Order Number “97379”,

- We will Shipment Lines along with following details

- We can see Shipping Method attached to Shipment

- Line Status will be Staged