Unit of measure is a value which specifies the quantity of an item. UOM is used in

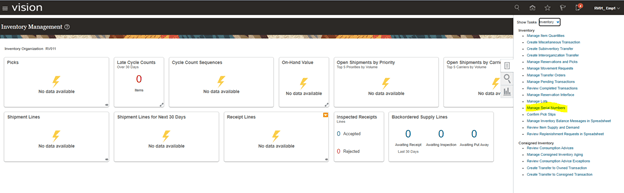

- Inventory Management

- Product Management

- Order Management

- Global Order Promising

Unit of Measure Class

Unit of measure classes represent groups of units of measure with similar characteristics. Creating unit of measure classes is the first step in unit of measure management. Each unit of measure we define must belong to a unit of measure class. Some of the UOM Classes are

- Count

- length

- Time

- Volume

- Mass

- Area

Each class has a base unit of measure. The base unit of measure is used to perform conversions between units of measure in the class. For this reason, the base unit of measure should be representative of the other units of measure in the class, and generally one of the smaller units. For example, you could use CU (cubic feet) as the base unit of a class called Volume. Unit of measure classes are not organization-specific. Default unit of measure classes are not provided.

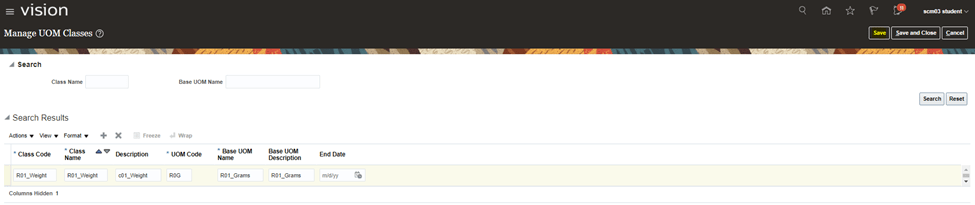

Below table depicts assigning Base UOMS to UOM Classes

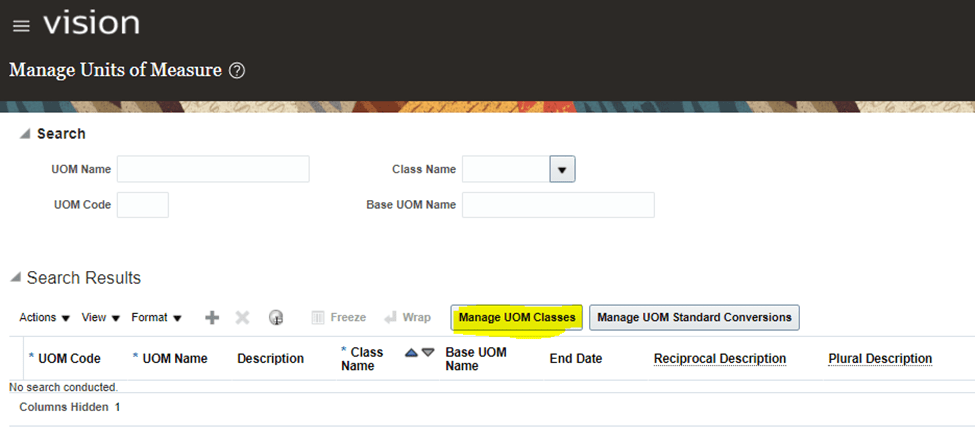

Step 1: Creation of UOM Classes

- Navigation ->Go to setup and Maintenance -> Click on Task Pane Carousel -> Click on Search -> Enter Task “Manage Units of Measure”.

- Click on Task to reach below screen. Click on Manage UOM Classes.

- Click on + button to create new UOM Classes.

- Enter following

- Class Code = “R01_Weight”

- Class Name = “R01_Weight”

- Description = “R01_Weight”

- UOM Code = “R0G”

- Base UOM Name = “R01_Grams”

- Base UOM Description= “R01_Grams”

- Click on Save.

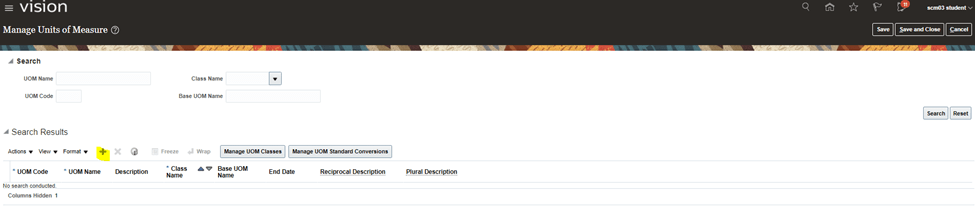

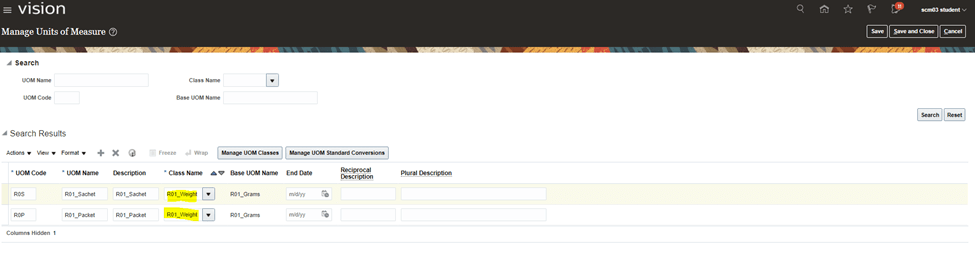

Step 2: Creation of Unit of Measures

- On Units of Measure screen, Click on + button to create New Unit of Measure.

- Create two Unit of Measure Code

- Enter UOM code = “R0S”

- UOM Name = “R01_Sachet

- Description = “R01_Sachet

- Select Class Name(R01_Weight) created in Step 1.

- Base UOM_Name “R01_Grams” will get defaulted.

- Repeat above steps for UOM code = “R0P”

Step 3: Unit of Measures Standard Conversion

- This is used to signify how two Unit of Measures are related to each other

- Click on Manage UOM Standard Conversions

- Click on + Button to create New Standard Conversion

- Make Below Entry

- Conversion for R01_Sachet

- UOM Name = R01_Packet

- Conversion = 20

- It signifies 1 R01_Packet = 20 Grams

- Conversion for R01_Sachet

- UOM Name = R01_Sachet

- Conversion = 10

- It signifies 1 R01_Packet = 10 Grams

- Hence using above conversion 2 R01_Sachet is equivalent to 1 R01_PACKET

- Conversion for R01_Sachet