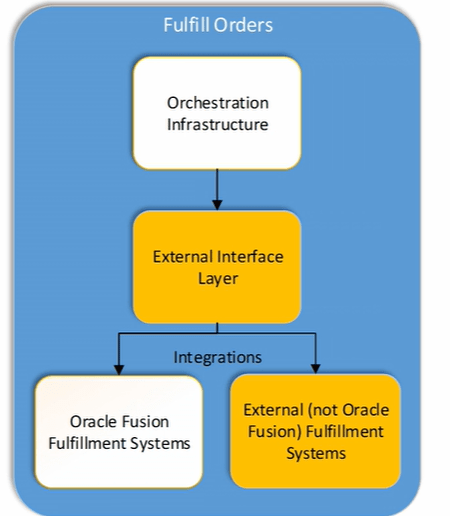

- Dropship: It is an Order fulfillment strategy where the Seller does not keep product(s) in it inventory, but relies on suppliers or contract manufacturers to build, store and ship orders to end customers.

- When a customer places on order for a drop shipped product, the seller issues a purchase order to the supplier/contract manufacture, for the item and provides instructions for shipping directly to the end- customer.

- The Suppliers or Contract manufacturers ships the product and then sends Invoice to Seller as part of ASN(Advance Shipping Note).

- Seller then send invoice to End Customer and get payment from Customer.

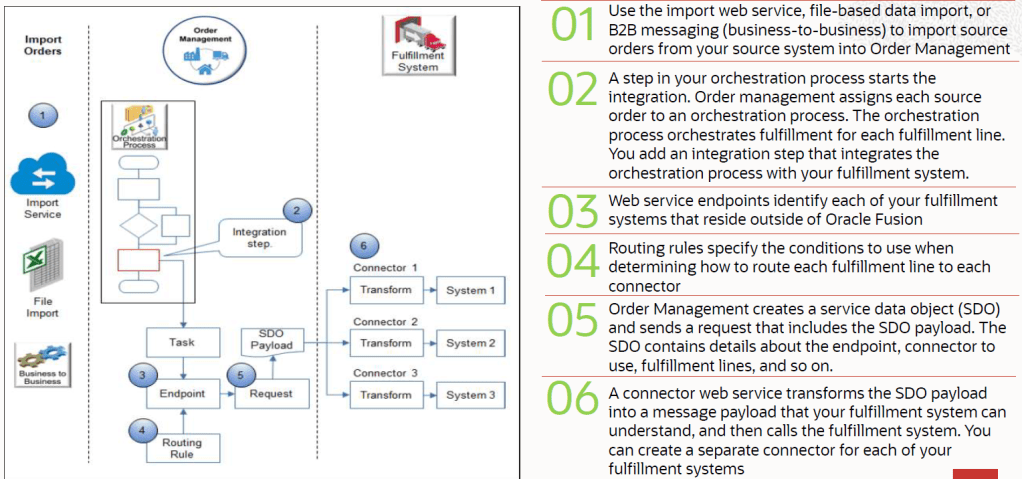

Different stages and communication happening in Drop Ship.

Stage 1: Interaction between Order Management(OM) and Global Order Promising(GOP).

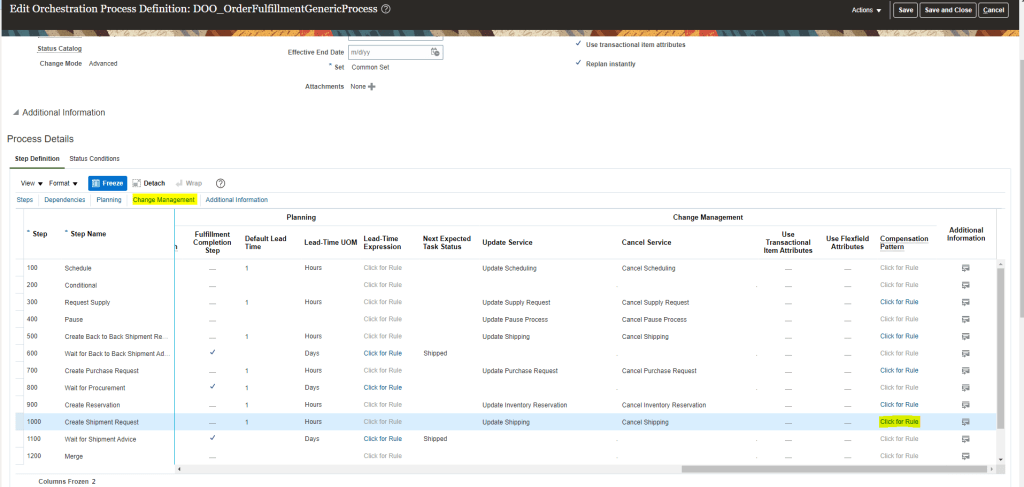

- Scheduling is the first step in Orchestration Process. OM sends request to GOP to schedule order.

- GOP checks sourcing rules and to figure out Supplier based on suppliers lead time, supplier capacity etc. and then assign Supplier to the order and responds to OM.

- OM knows that order will Drop Shipped.

- Fulfillment line is set to Scheduled Status.

Stage 2: Interaction between Order Management(OM) and Supply Chain Financial Orchestration(SCFO).

- OM sends request to SCFO for requisition Business unit and organization.

- SCFO determine the Drop Ship financial flow.

- SCFO returns requisition BU and Organization to OM which is used by OM for purchase request.

Stage 3: Interaction between Order Management, Procurement and Supplier.

- OM sends a purchase request to Procurement which then creates a requisition.

- Blanket Purchase agreement for Item and Supplier if exist, details are fetched from it to get the price amount etc.

- Fulfillment line status in OM, changes from “Scheduled” to “Requisition Created”.

- Purchase order gets created and sent to supplier for fulfillment and notification is sent to OM.

- Fulfillment line status changes to “Awaiting Shipping”.

Stage 4: Interaction between Order Management, SFO/SCFO, Supplier and Receiving.

- Supplier ship goods against PO and creates Advance shipment Notice(ASN).

- Oracle fusion Receiving records a logical receipt for ASN and notifies OM.

- OM calls “getshipment” web service to gets shipment details from receiving such as ASN, WAYBILL, Bill of Lading, Item and Shipped Quantity .

- If entire order quantity is shipped then Fulfillment line status changes to “Shipped”.

- SFO identifies and execute the financial flow once ASN gets created.

Stage 5: OM and Receivables.

- OM sends requests to Receivables to bill the customer.

- Fulfillment line status changes to “Awaiting Billing“.

- Receivables creates invoice and notifies OM, post which Fulfillment line status changes to “Billed“.

- OM closes the fulfillment line once the customer is billed.

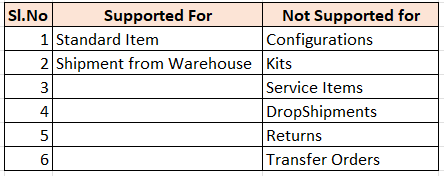

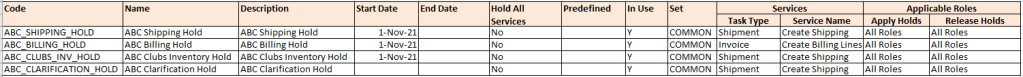

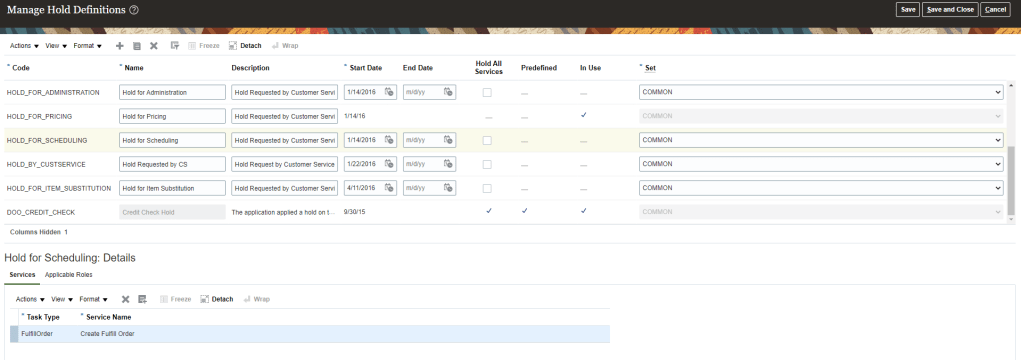

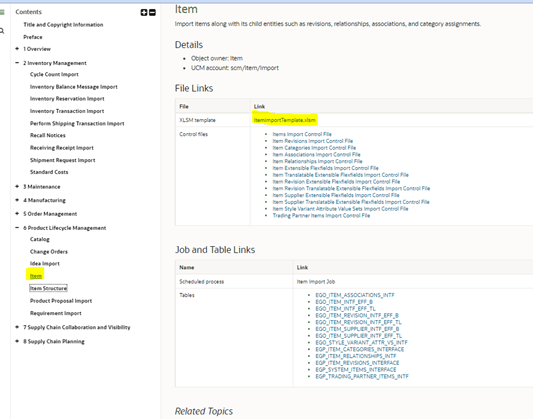

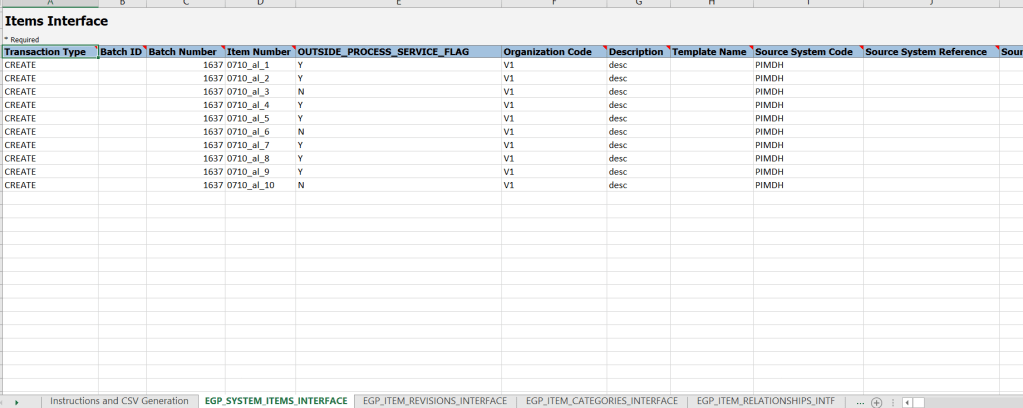

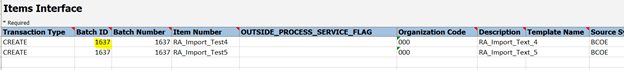

Drop ship Mandatory Setups

Below are the setups to be done for Drop Ship Order Fulfillment.

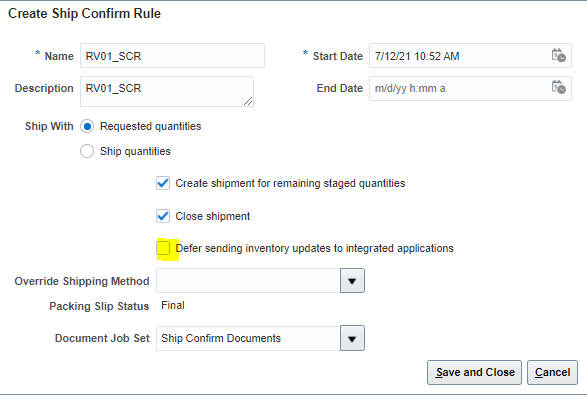

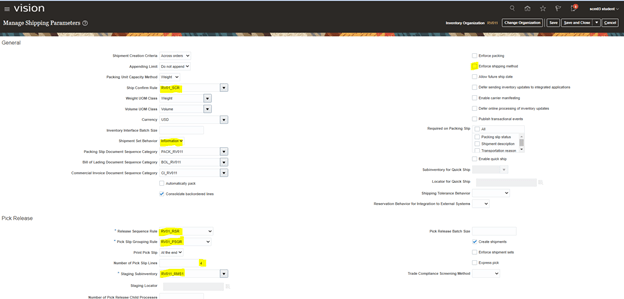

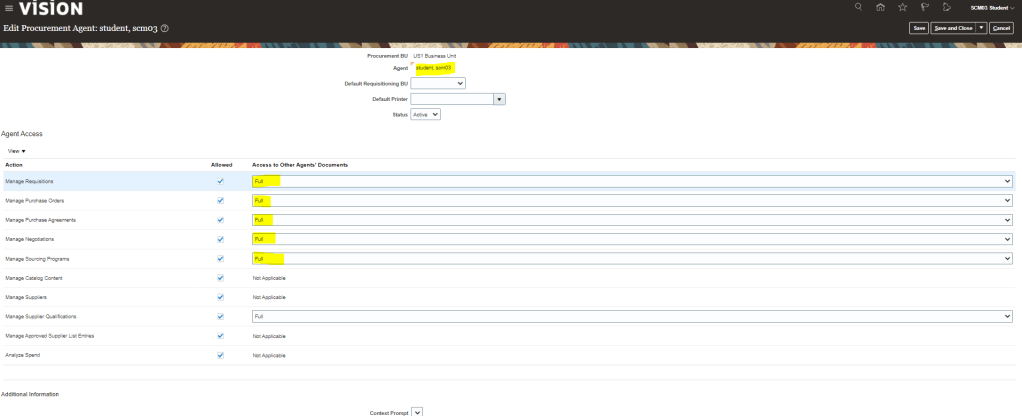

Setup 1 : Configure User profile to enable them to create BPA

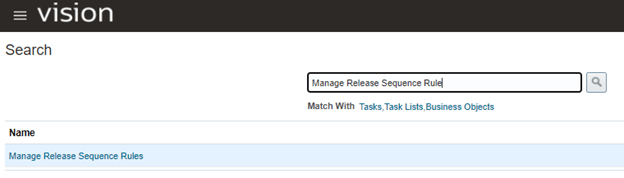

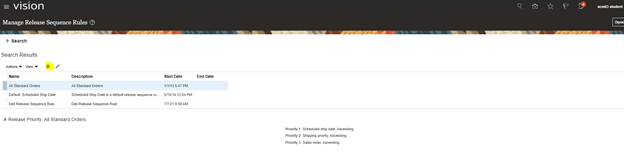

- Navigation : Setup and Maintenance -> Click on Search task next to Task Carousel -> Enter task “Manage Procurement Agent“.

- Ensure User profile is setup else while creating Purchase Agreement, Procurement BU, will not appear.

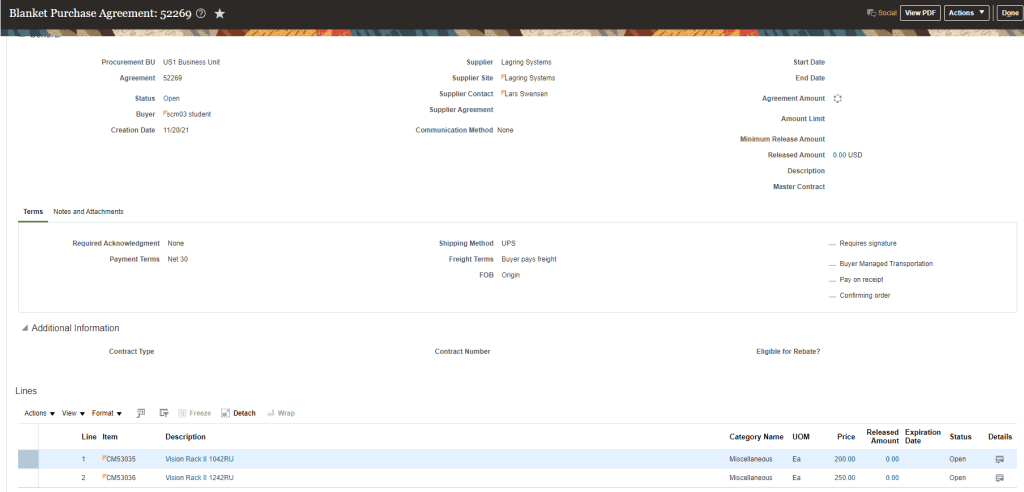

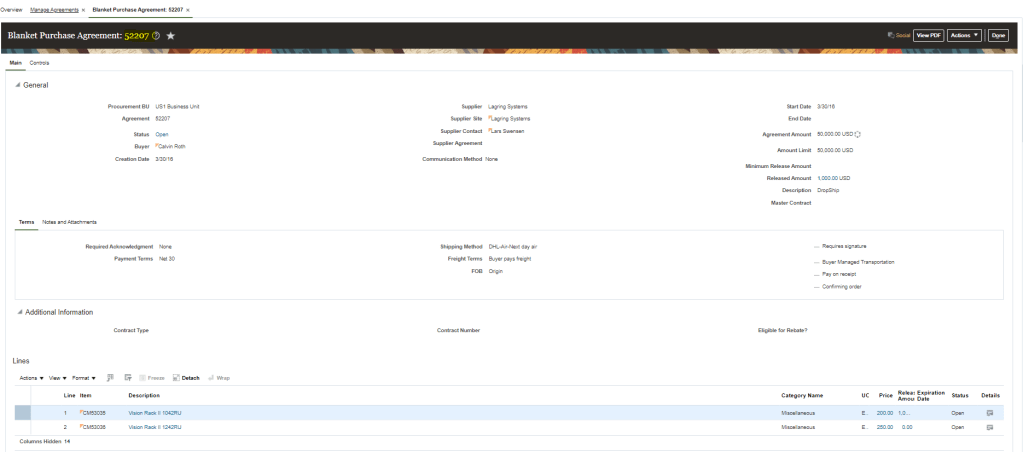

Setup 2 : Create Blanket Purchase Agreement (BPA).

- Navigation : Under same user profile of SCM03, Go to Procurement -> Purchase Agreement -> on right side “Create Agreement”.

- Create Agreement for Supplier “Lagring Systems”.

- Add Items which needs to be added as part of BPA.

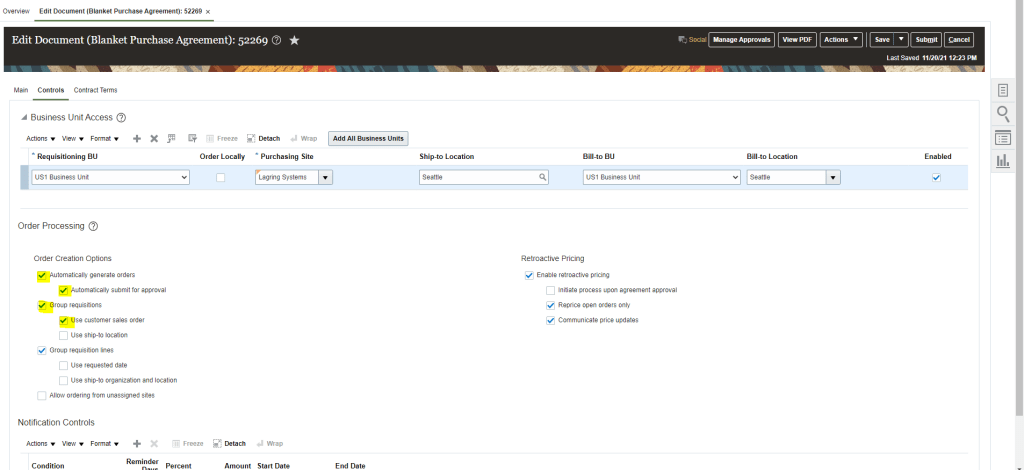

- Under Control tab, ensure below boxes are checked.

- Click on Submit and BPA gets created

- For our testing purpose we will be using BPA created for user profile “ROTH.CALVIN.” BPA number is “52207“.

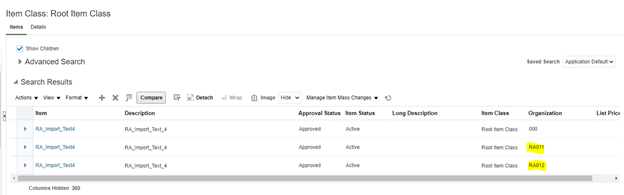

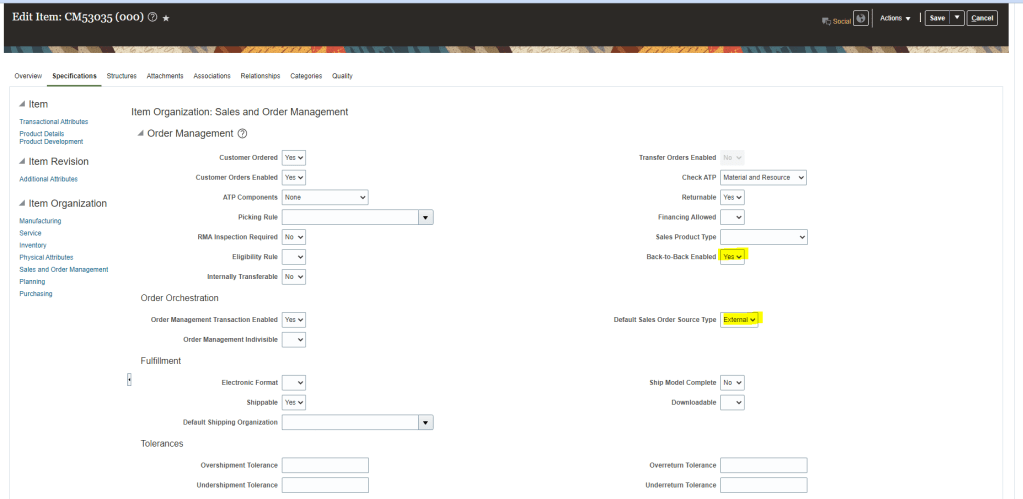

Setup 3: Item should be Setup with Back to Back Enabled as “Yes”

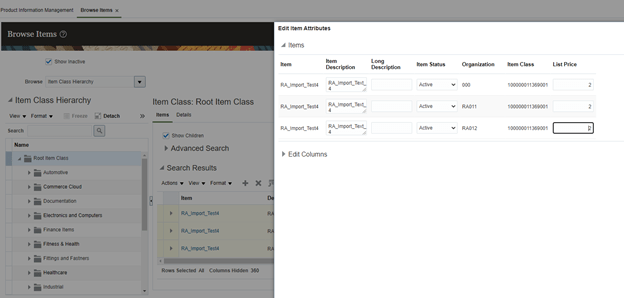

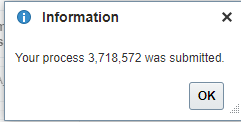

- Navigation : Product Management -> Product Information Management -> Browse Item -> Specifications -> Sales and order Management

- Back to Back Enabled should be “Yes“.

- Default Sales Order Service Type = “Enabled”.

- Under Purchasing Tab, ensure Purchasable as “Yes” and List price should have a value.

- Under Planning Tab, ensure Planning Method is “MRP Planning”.

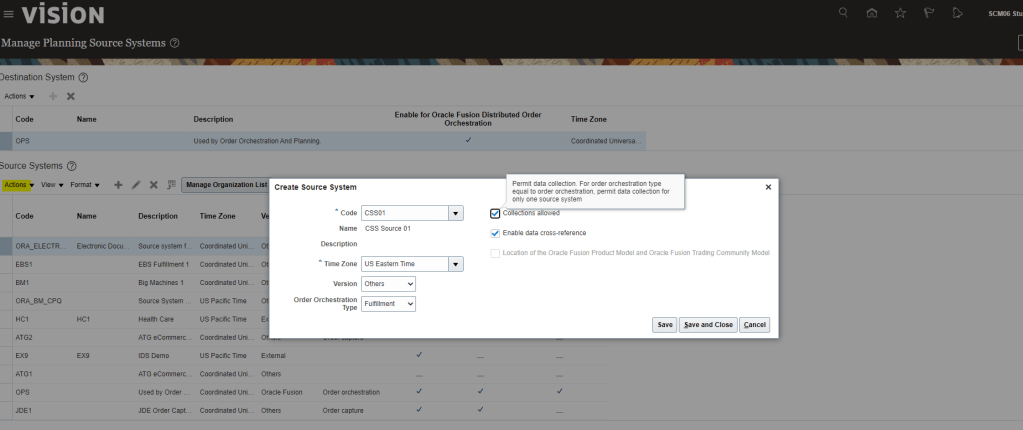

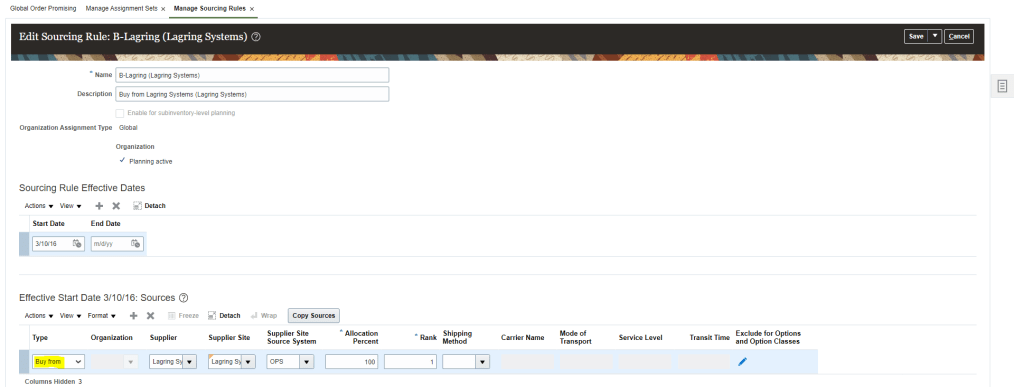

Setup 4: Global Order Promising Setup

Sourcing Rule Setup.

- Sourcing Rules should be Setup with “Buy From” the supplier.

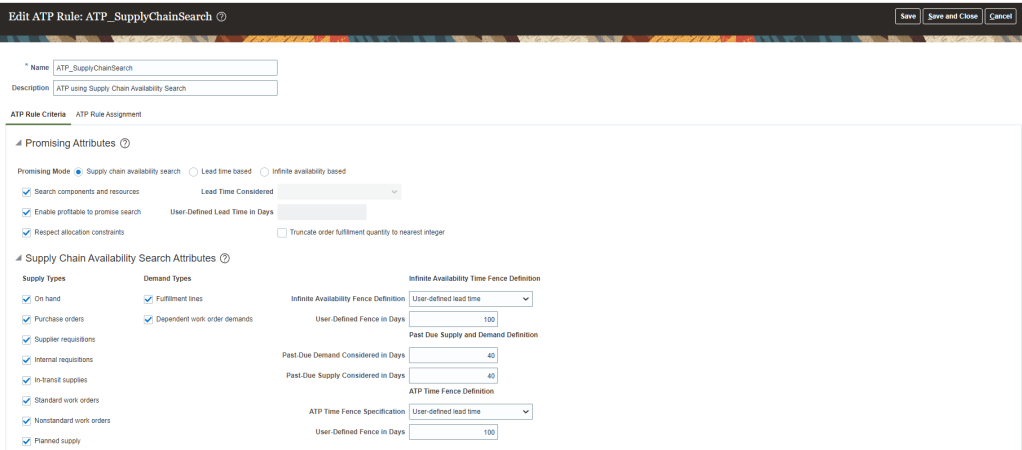

ATP rule

- Create ATP rule which has all below setup

Assignment set.

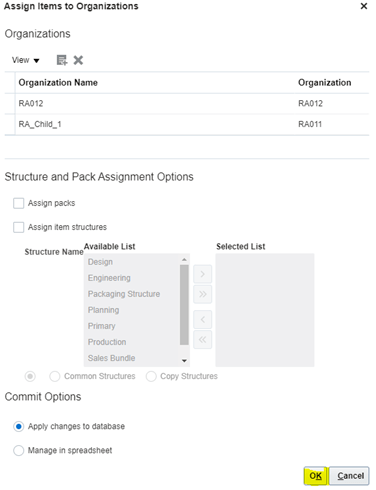

- Management Assignment set should be setup for the Item with Assignment level as “Item” and Sourcing rule which was setup in step 4. Due to assignment level of “Item”, Order Fulfillment becomes DropShip”. If we would had kept Assignment Level as “Item and Org”, it will become Order Fulfillment would become “Back to Back”.

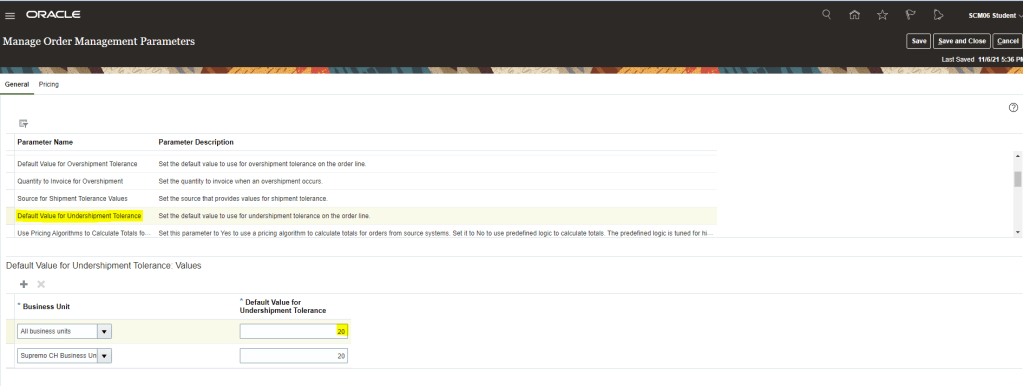

Setup 5: Preparer should be setup in Order Management Parameters

- Ensure Preparer is setup for the Business unit where transaction is taking place.

Setup 6: Sales Order Fulfillment is enabled in Procurement offerings

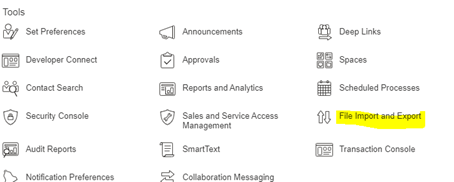

- Navigation : Go to Setup and Maintenance -> select offering as Procurement -> Actions -> Change Feature Selection

- Ensure Customer Sales Order Fulfillment is enabled.

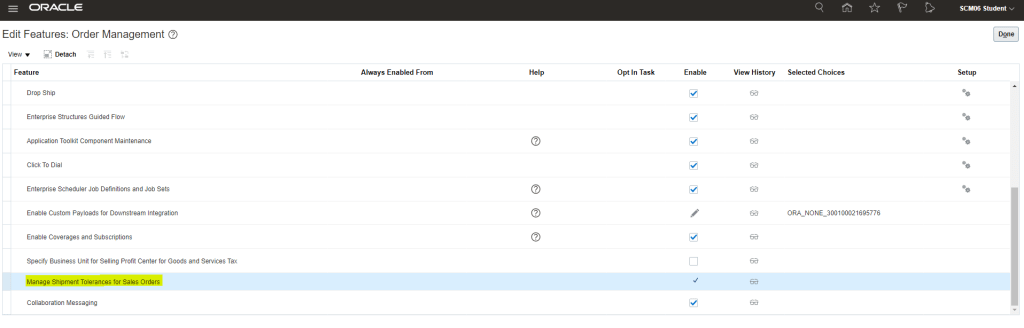

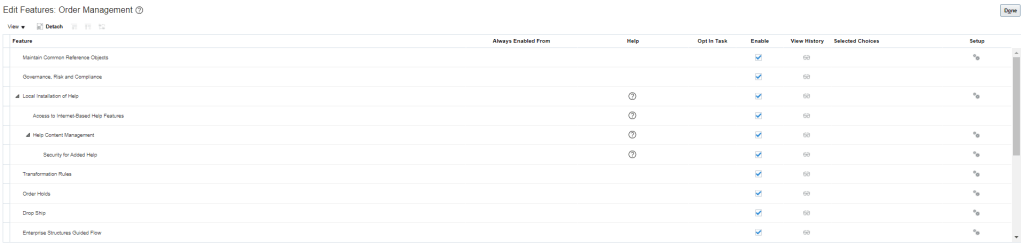

Setup 7: Drop Ship should be enabled under Sales Order offerings

- Navigation : Go to Setup and Maintenance -> select offering as Sales Order-> Actions -> Change Feature Selection.

- Ensure Drop Ship is enabled.

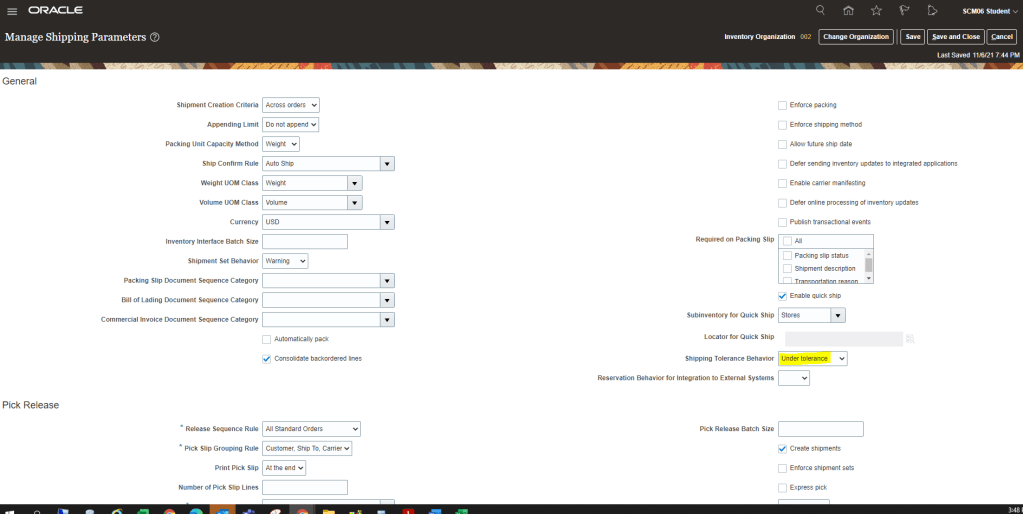

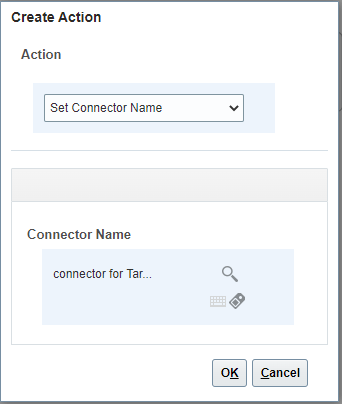

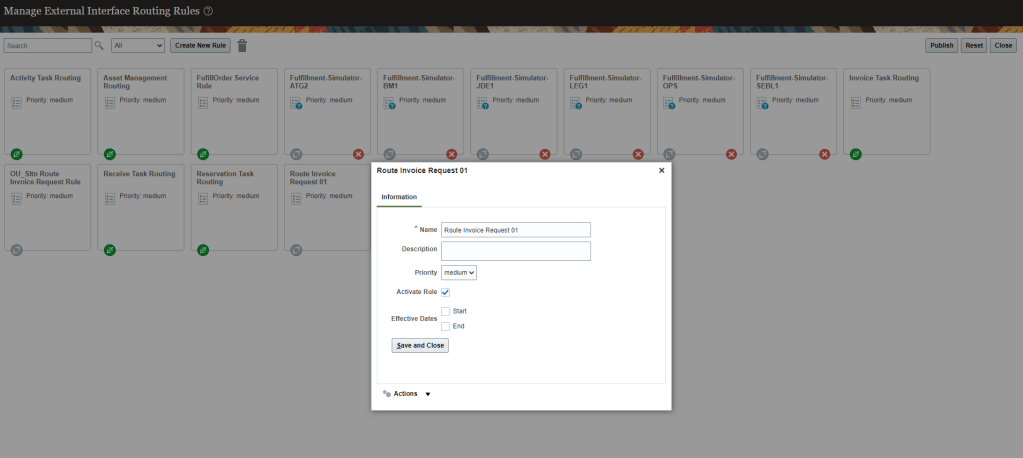

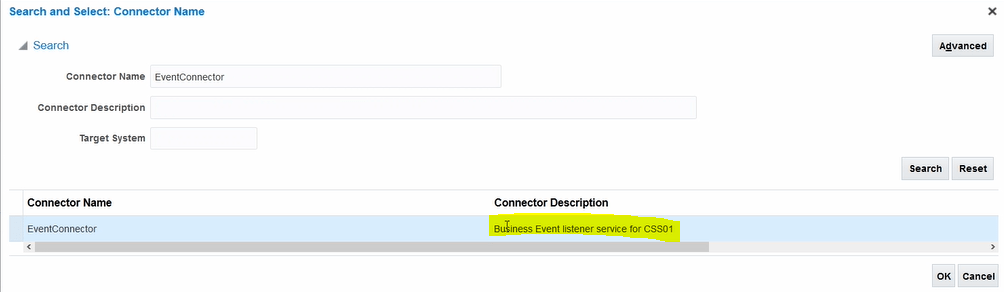

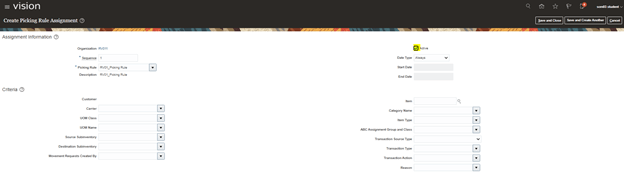

Setup 8: Drop Ship Financial setup

- Navigation : Go to Setup and Maintenance -> select task : “Manage Drop Ship Financials”.

- Ensure setup exist.

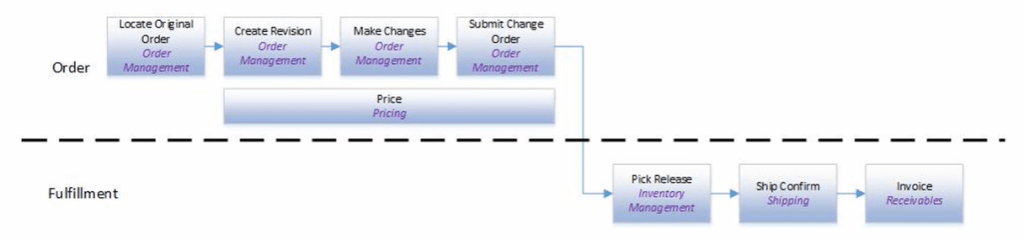

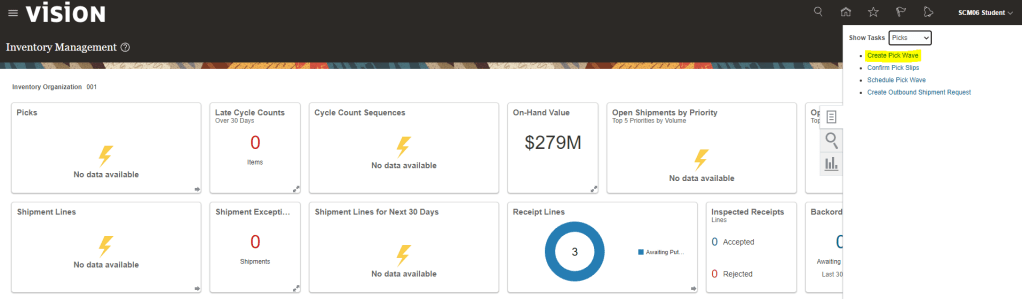

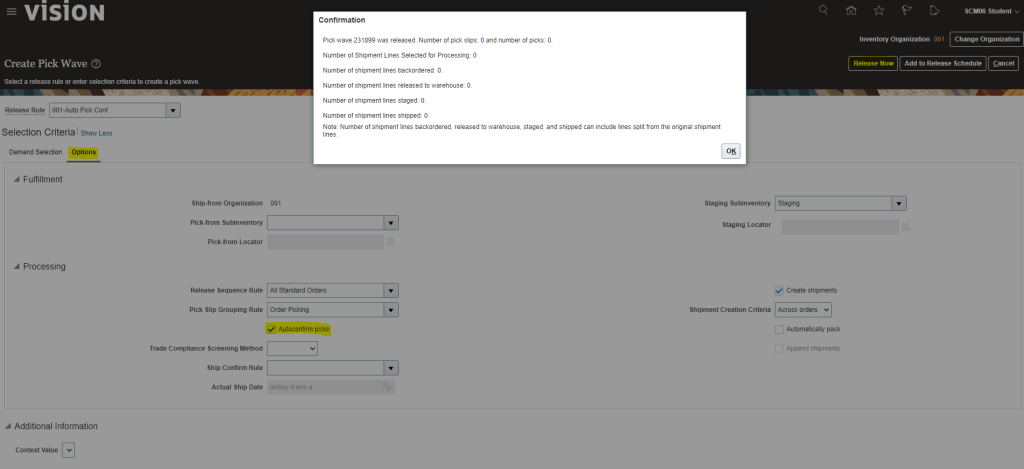

Drop Ship Creation Process

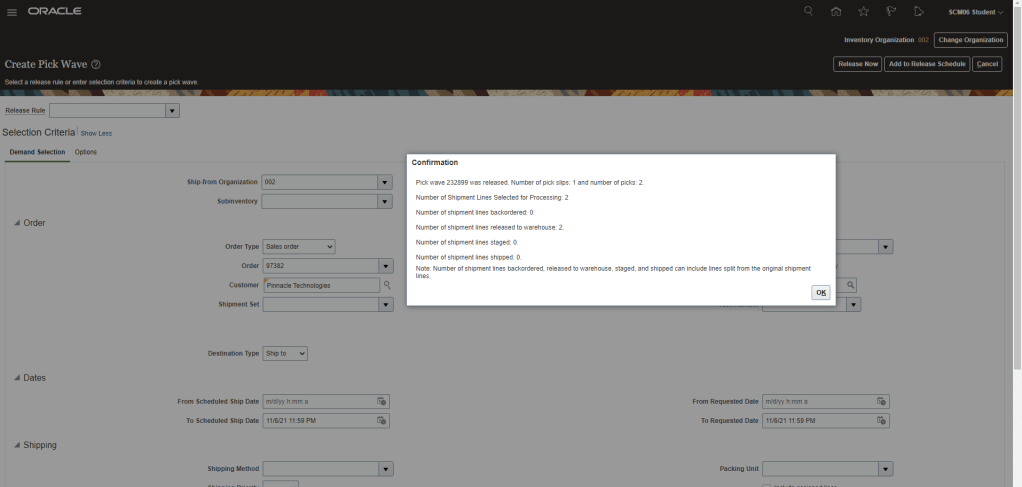

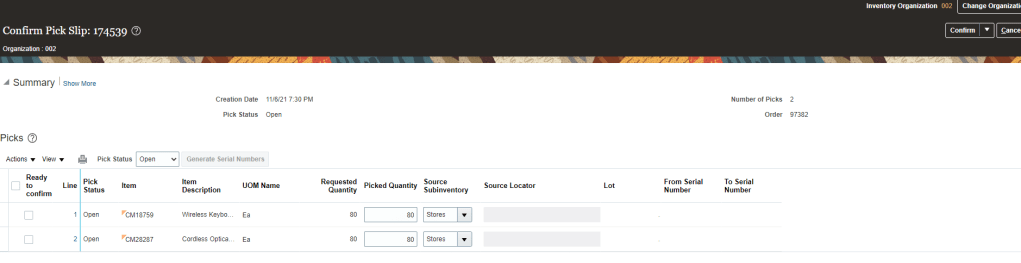

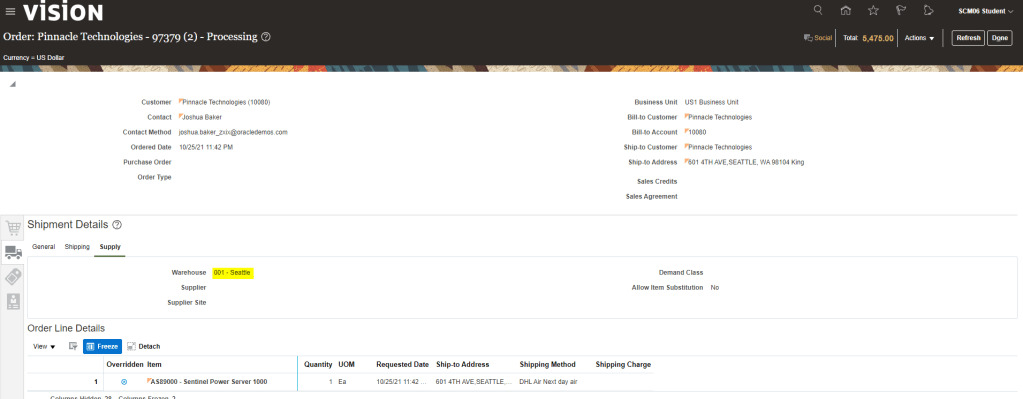

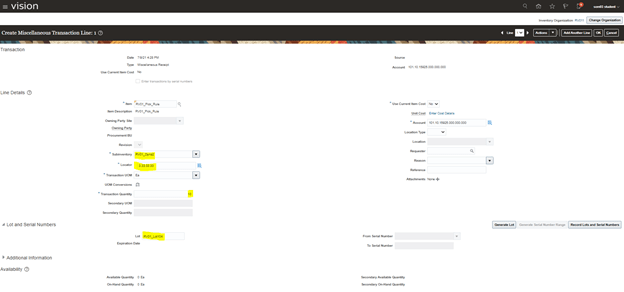

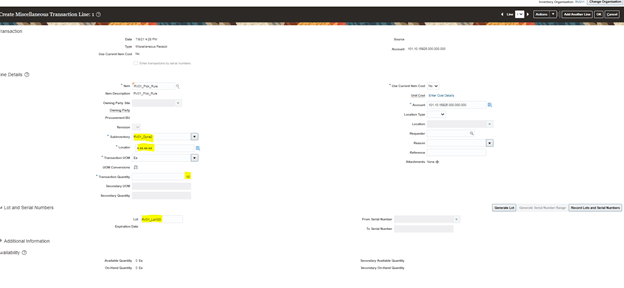

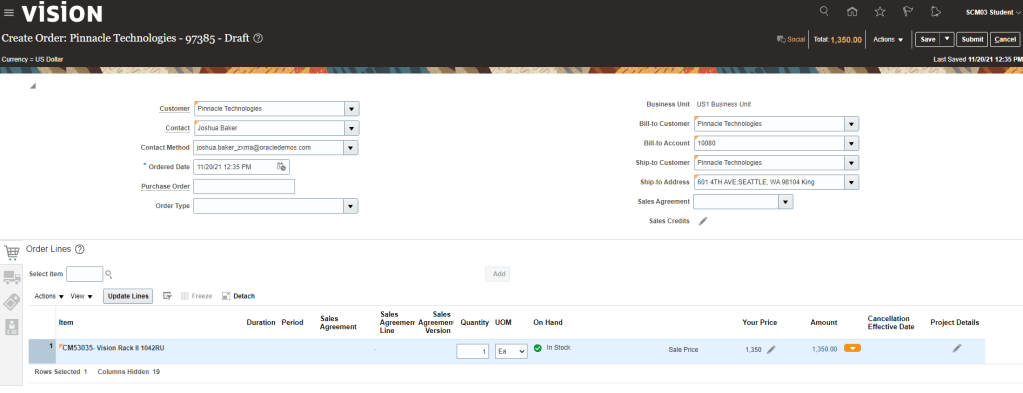

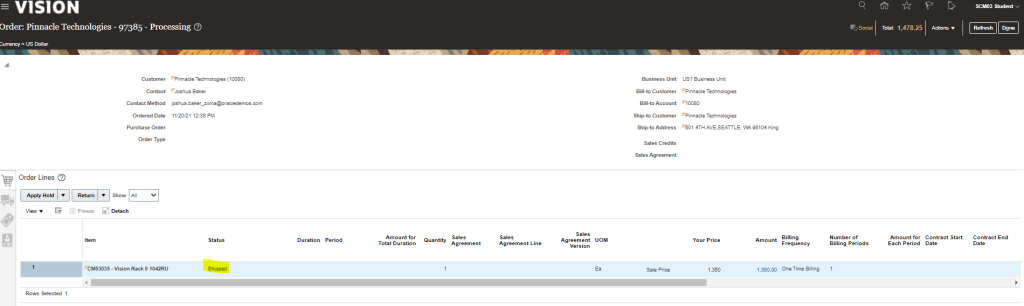

Step 1: Create Sales Order

- Create sales order for item “CM53036”

- Set Receive date is 10 calendar days from today

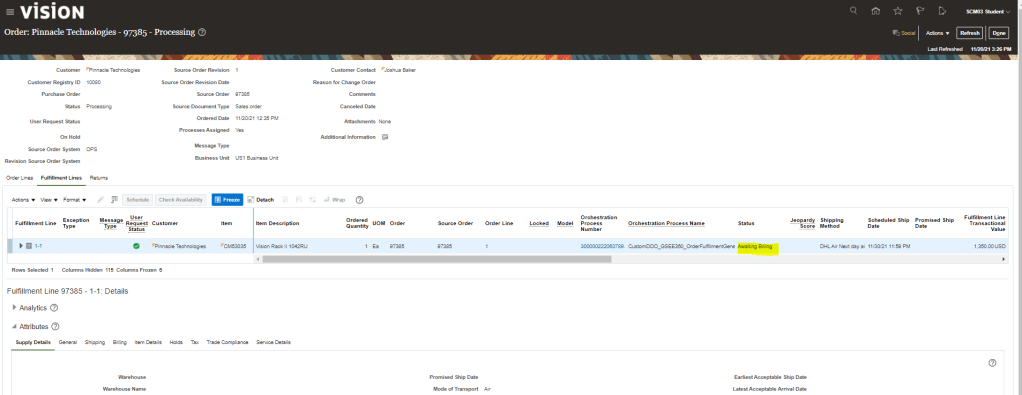

- Switch to Fulfillment View

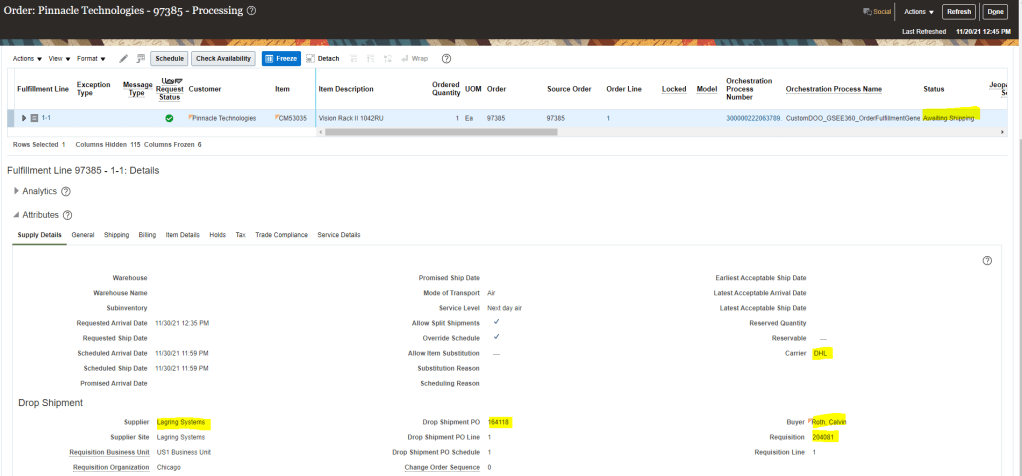

- Fulfillment Status is first set to “Not Started” thereafter it changes from Not Started -> Scheduled -> Requisition Created and then Awaiting Shipping.

- Under fulfillment line view -> Drop Shipment -> Supplier Name is set to “Lagring System”

- Now fulfillment line Status change to “Awaiting Shipping”.

- Drop Shipment PO number gets created

- Supplier Remains the Same

- Buyer Gets assigned

- Purchase Requisition Number gets created

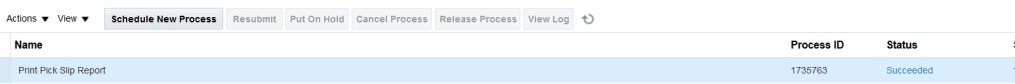

- Click on Orchestration Process number to see the progress of each line.

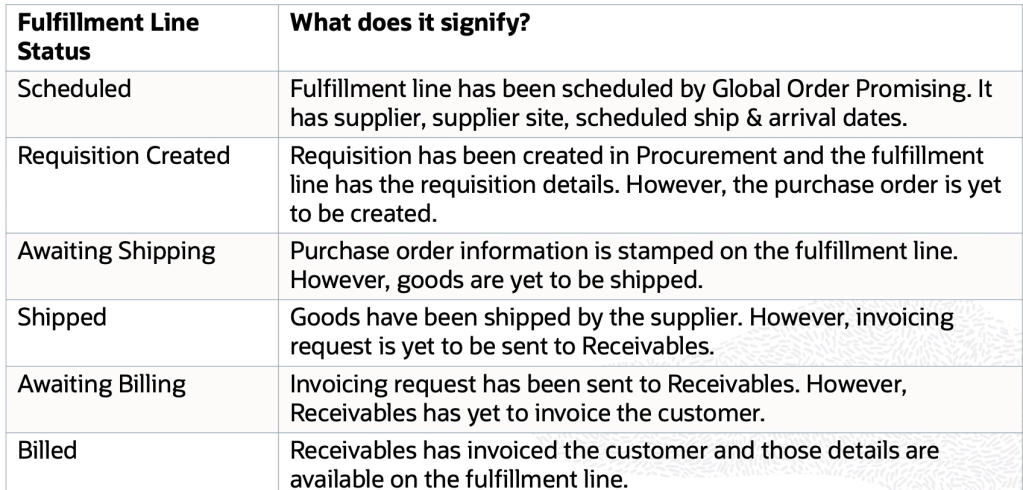

- Below are different statues of fulfillment lines and what they signifies.

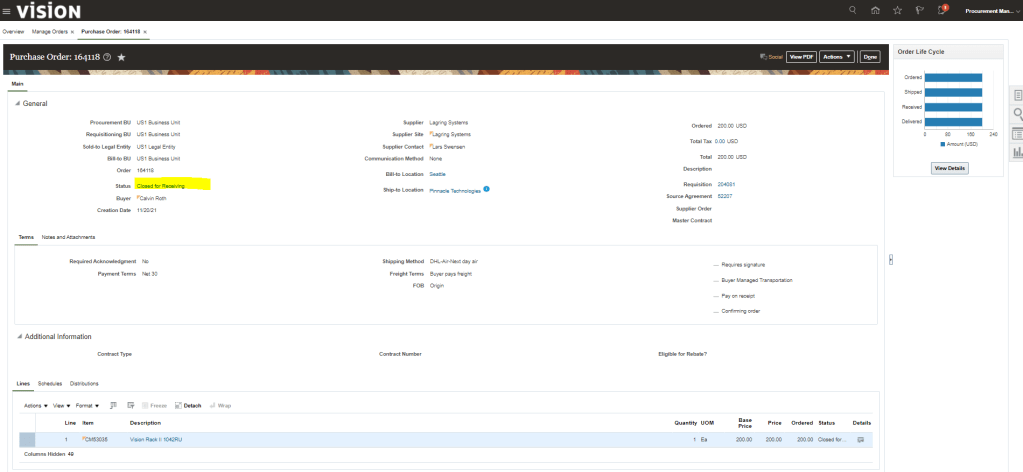

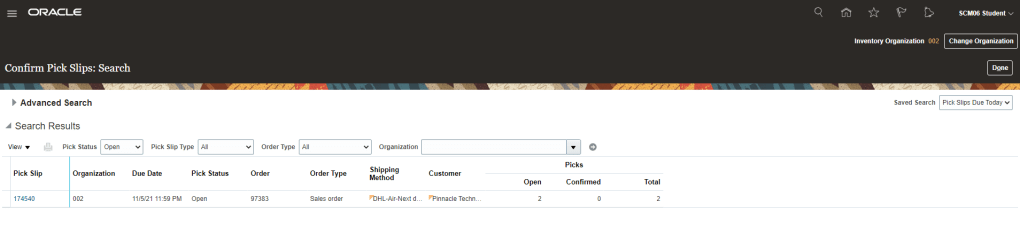

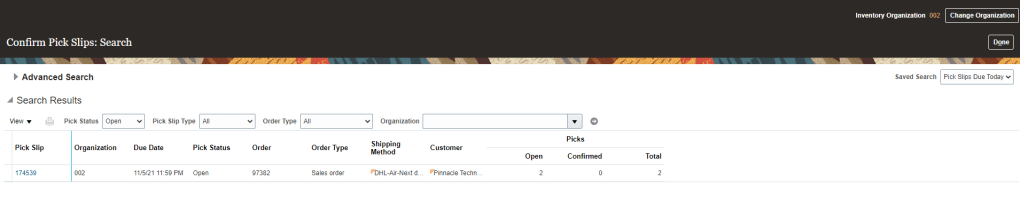

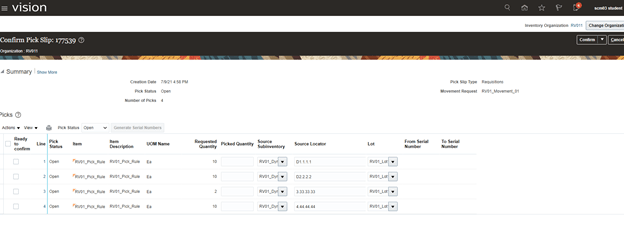

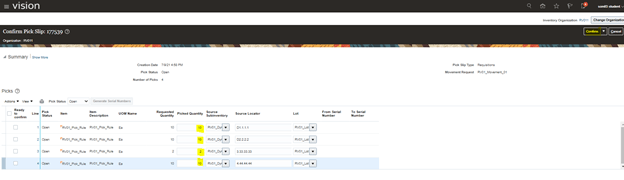

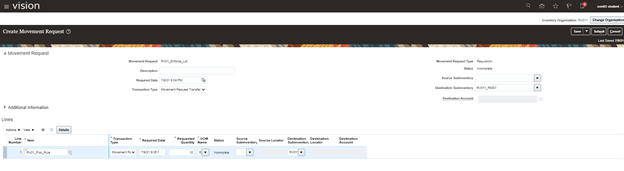

Step 3: Verify status of Purchase order

- Login as Calvin Roth to see details of Purchase order and Purchase Requisition

- Screenshot of Purchase Order

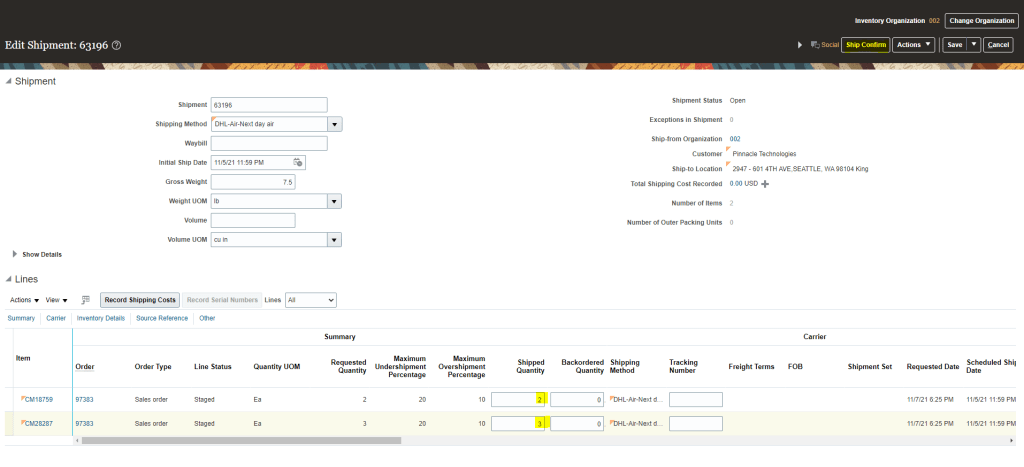

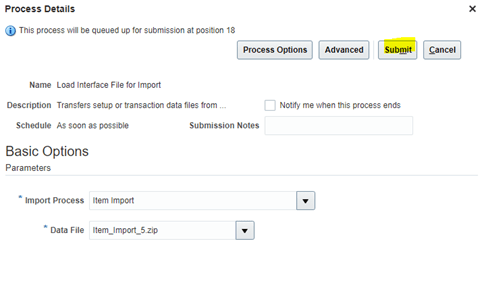

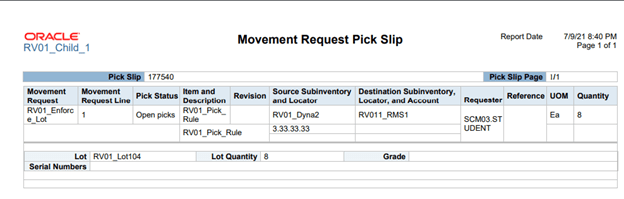

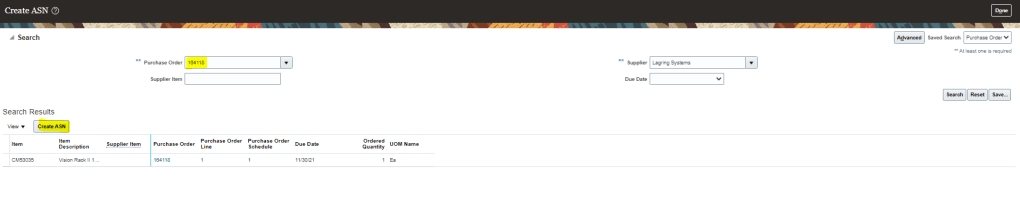

Step 4: Create ASN (Advance Shipping Notice)

- Logout and Login as supplier “Lars Swensen”.

- Go to Supplier Portal and See Pending Action

- Click on Create ASN below Shipments Tab.

- Enter details for shipment and click on Submit.

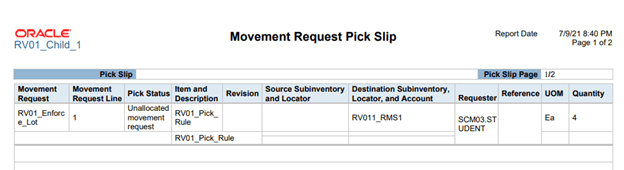

- This is how a sample Packing Slip looks.

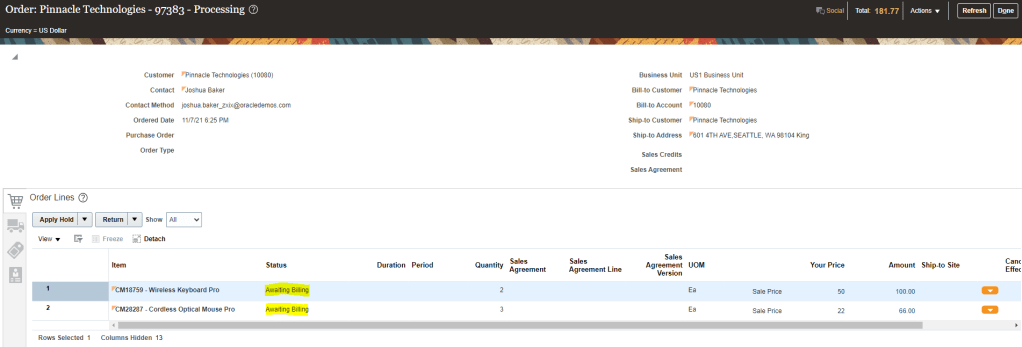

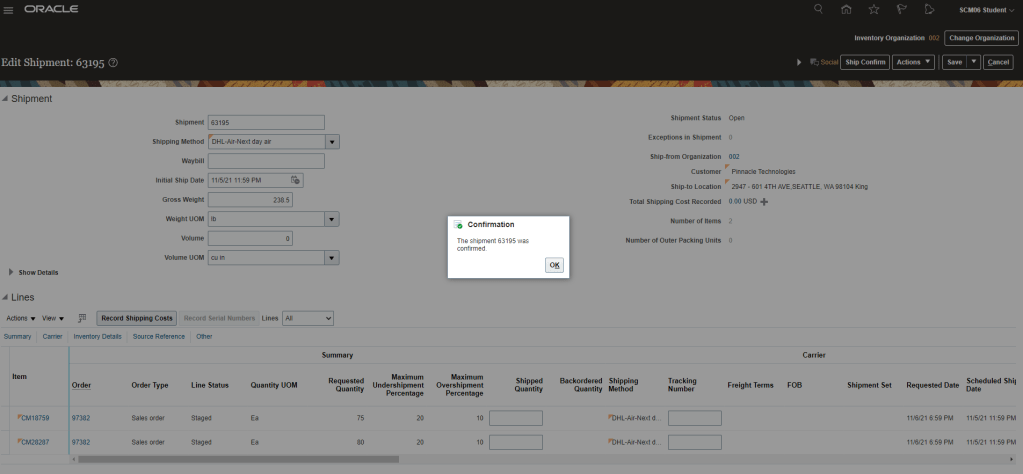

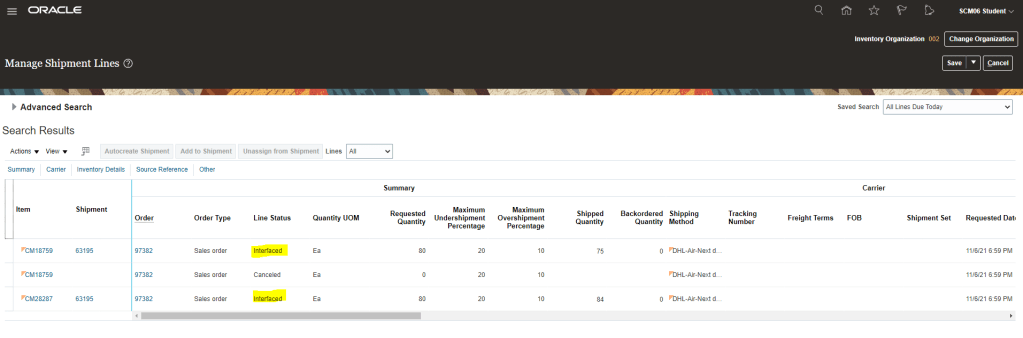

Step 5: Verify status of Sales Order

- Log out of System, Clear Cache and then Login as SCM03.

- Status first become “Shipped”.

- Then status changes to “Awaiting Billing”

- Status of Fulfillment Line also becomes “Awaiting Billing”

- Orchestration Process status details to become “Shipped“.

Step 6: Verify status of Purchase Order

- Login as user profile “Calvin Roth” to verify status of Purchase order. It should be in “Closed” status.