Pre-requisite : Refer link to create/understand BI Fusion Report from Scratch

https://wordpress.com/post/ravidubey.work/372

Below steps explain how to create parameterized BI report

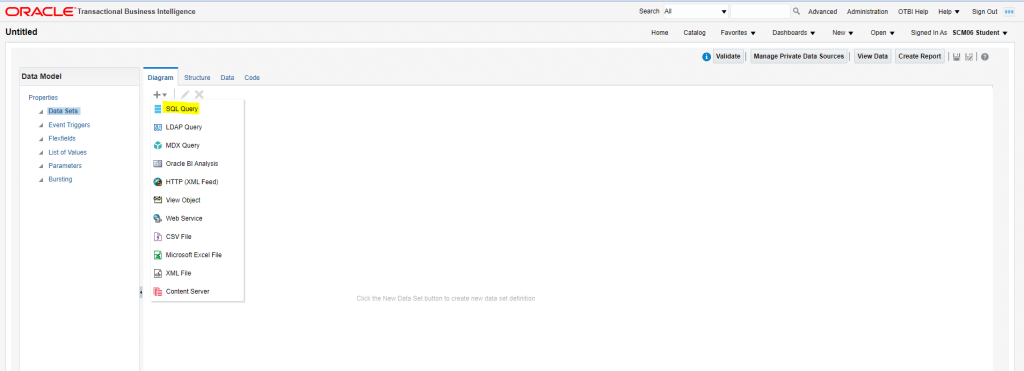

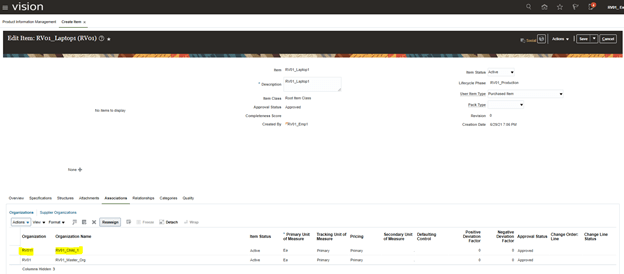

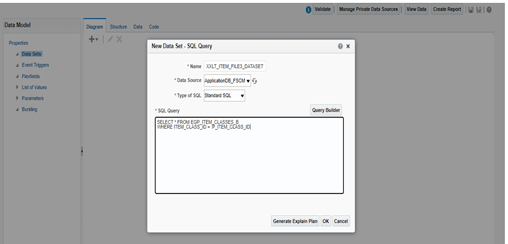

Step 1: Create New DATA MODEL

- Go to Menu Option New

- Select Data Model

- Click on + Icon

- Select SQL Query

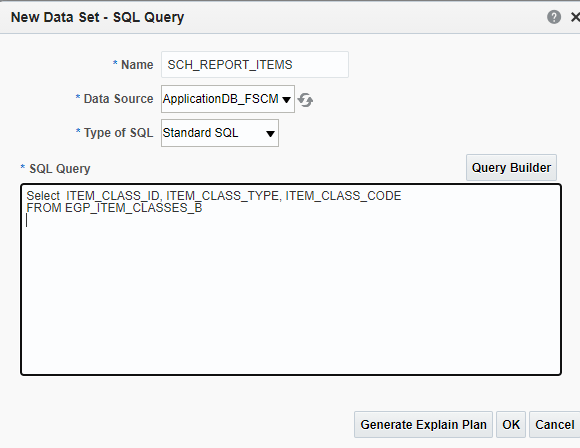

- Create a Data model with below SQL query

SELECT * FROM EGP_ITEM_CLASSES_B WHERE ITEM_CLASS_ID = :P_ ITEM_CLASS_ID

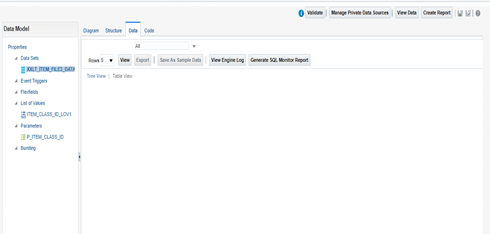

- Once you click OK, below screen will appear

- It will ask to create Parameter Value for which we will need List of Values.

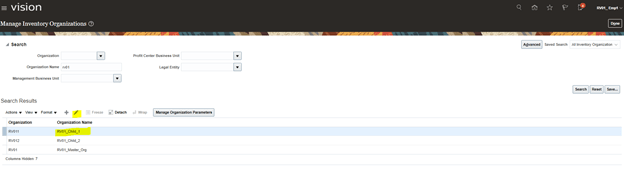

- On left hand side there is List of Values, create a variable ITEM_CLASS_ID_LOV1 with SQL query

- Go to Parameter Values section on left hand side and select the List of Values. Do remember to select Menu as Parameter Type.

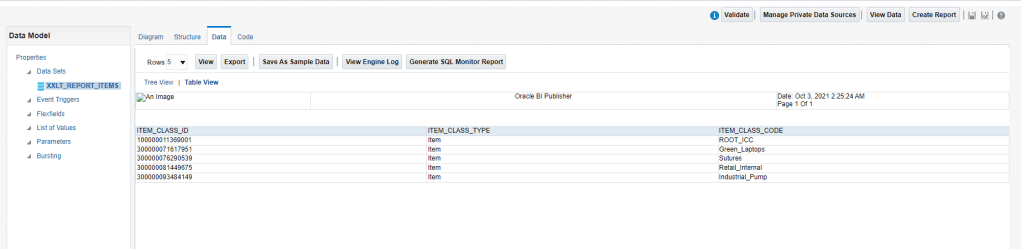

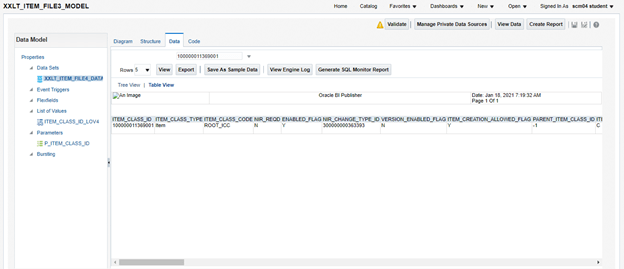

- Once data set is created and saved successfully. Go to Data View

- Choose Item Id from above list and select View.

- It will show data for selected Item id.

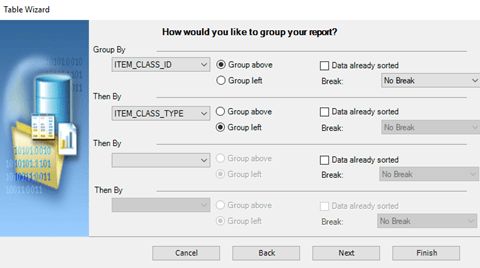

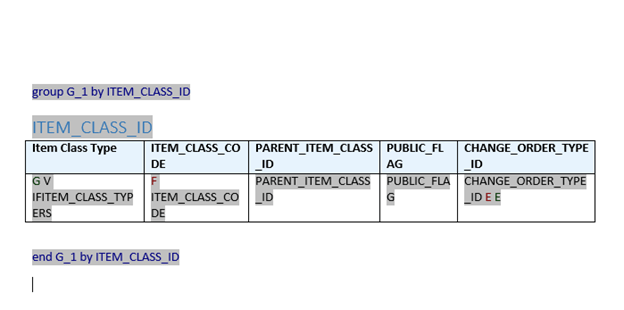

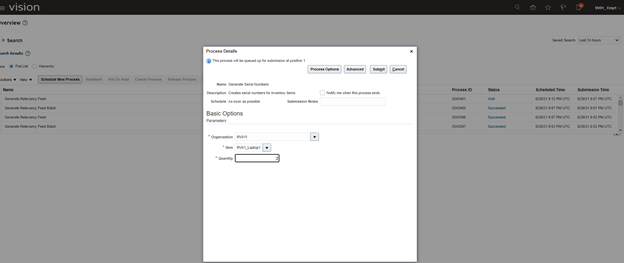

- Export the data and perform steps 2 and 3 of Report Generation from below link

https://wordpress.com/post/ravidubey.work/372

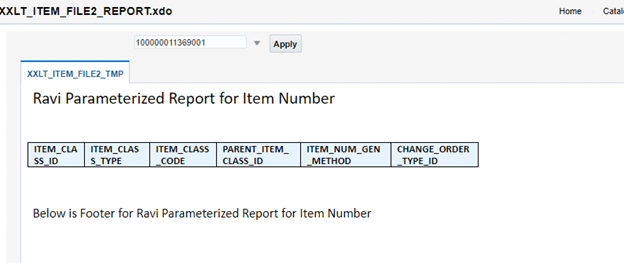

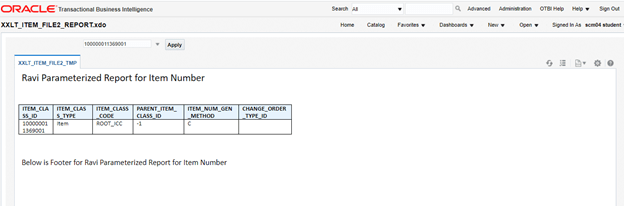

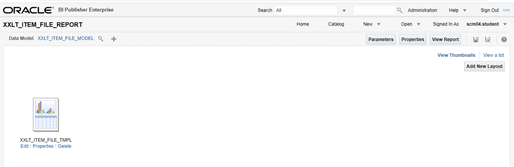

- While running Report enter Parameter value in Left hand side of Apply button and Click on Apply Button. Below report will be displayed in PDF format